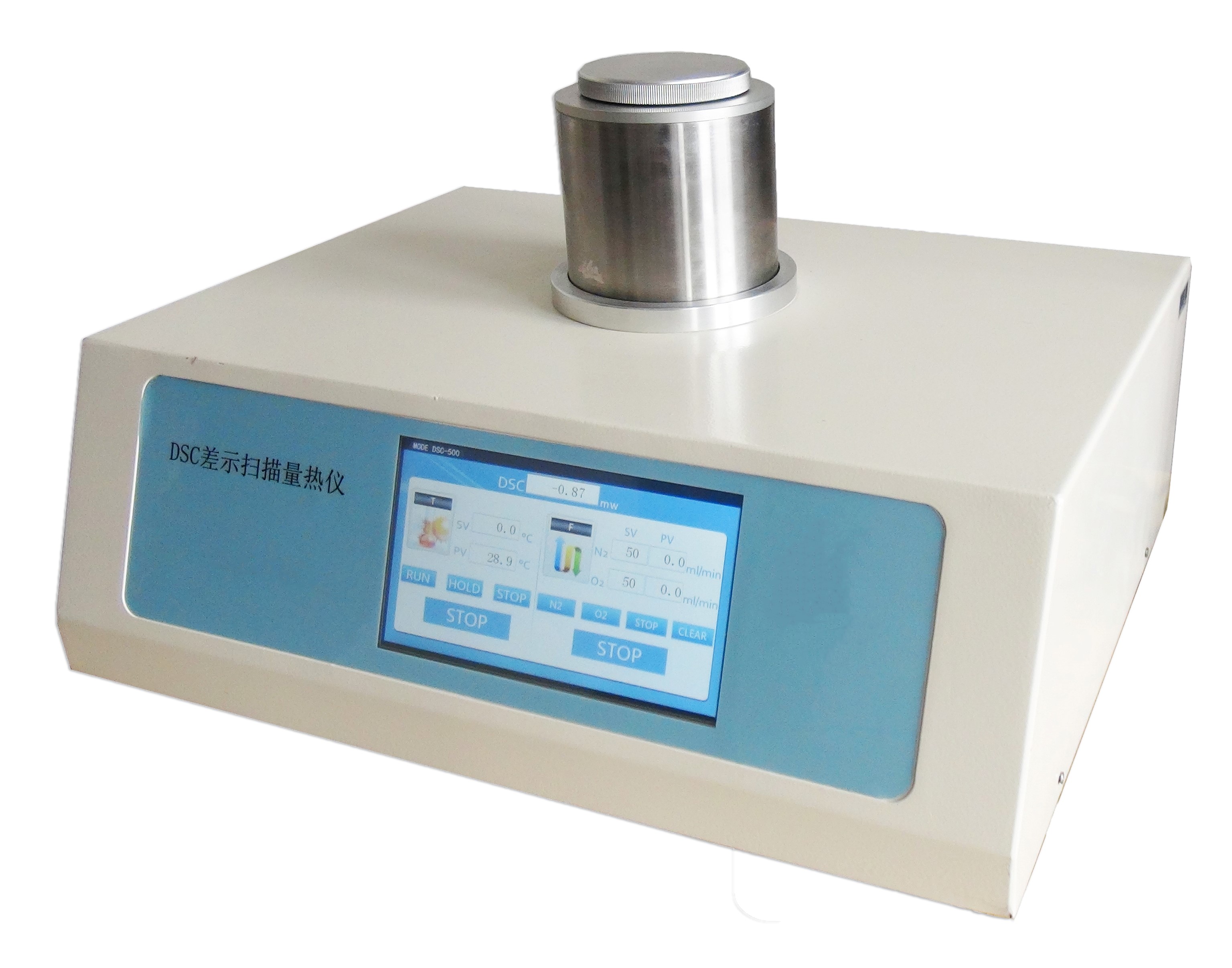

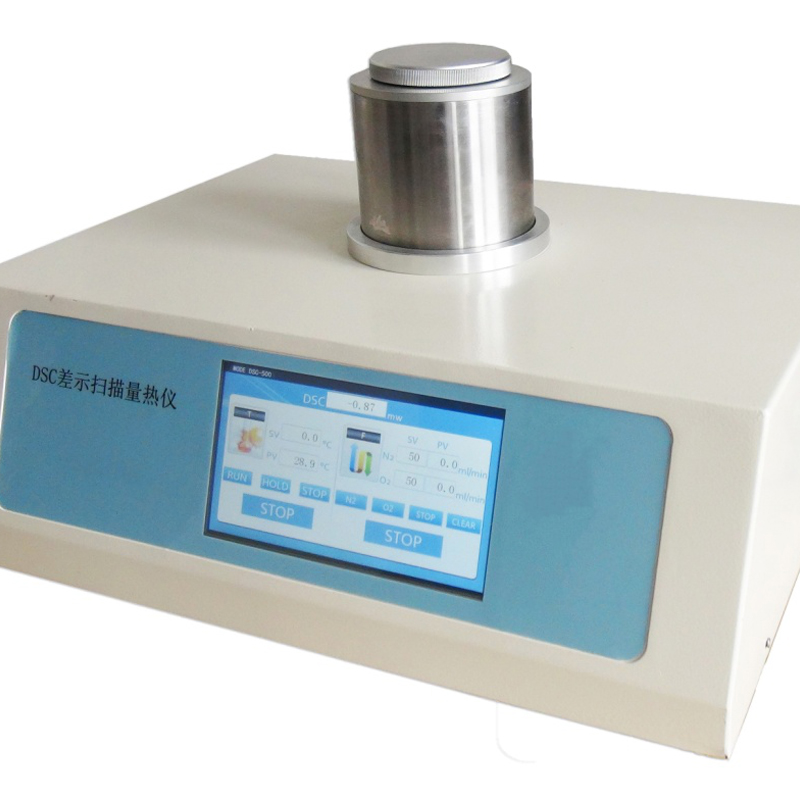

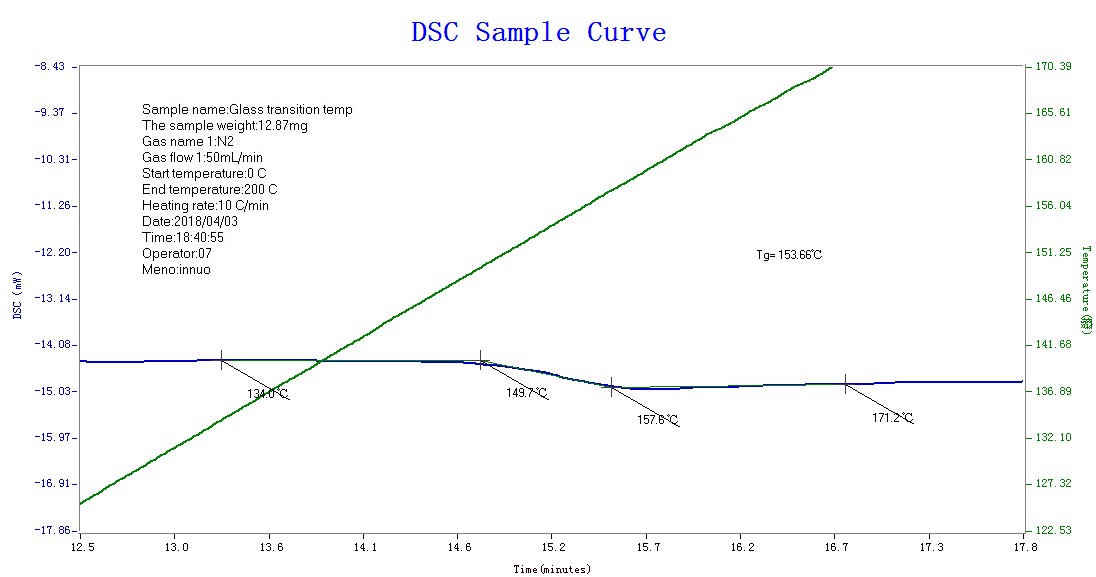

DSC-500B DSC Differential Scanning Calorimeter

NO:Touch Screen, Room Temp. ~ 500°C, Oxidation induction time test, Melting point test, Glass transition temperature test fEasy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Temperature Range: Room Temp. ~ 500°C

1. Simple Introduction

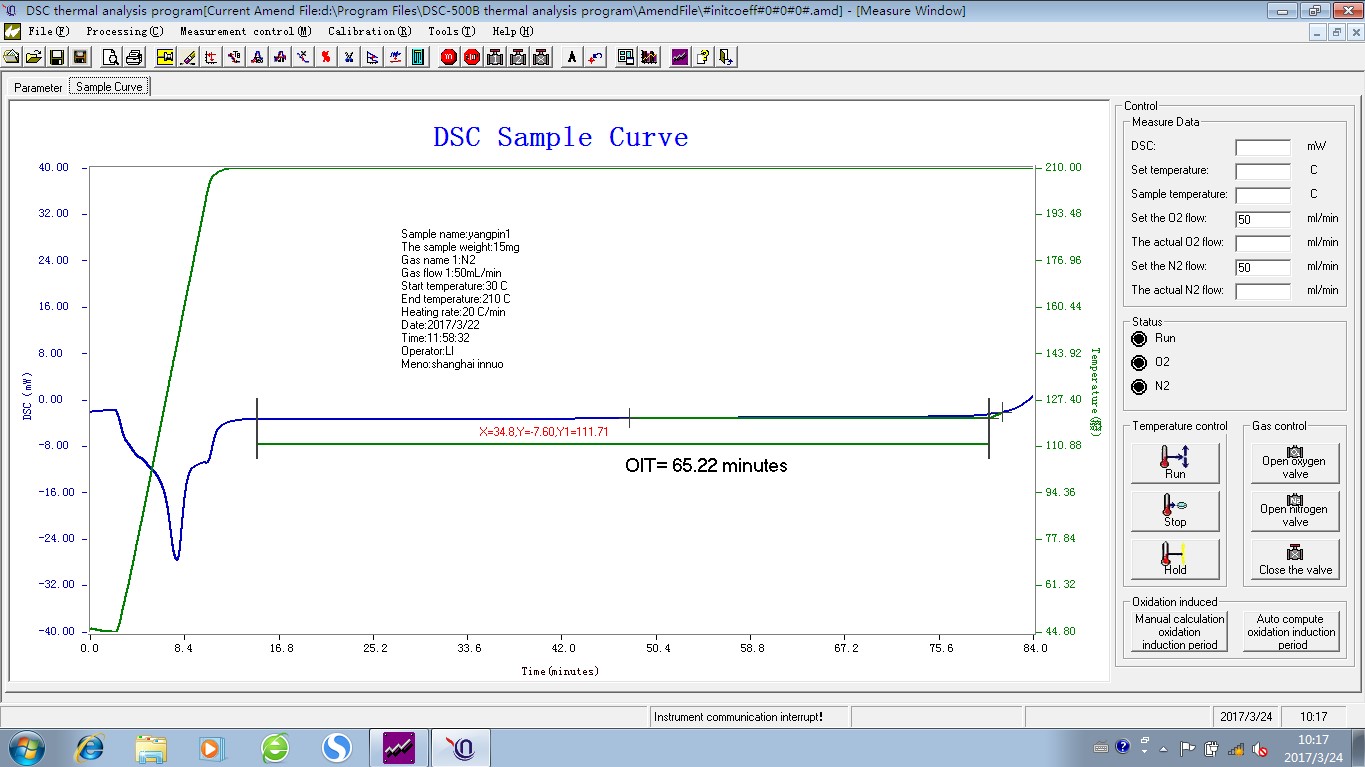

DSC-500B is a touch screen type, specially testing polymer material oxidation induction period test, customer one-key operation, software automatic operation.

Conforming the following standards:

ISO 11357-2:1999 / GB/T 19466.2- 2009

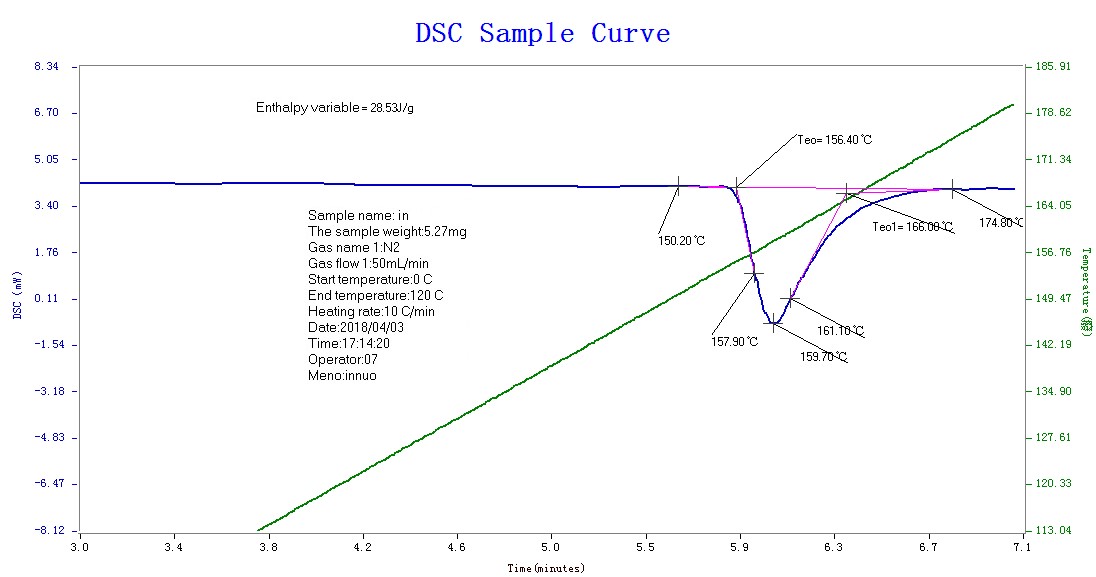

ISO 11357-3:1999 / GB/T 19466.3- 2009

ISO 11357-6:1999 / GB/T 19466.6- 2009

2. Featues

1. Industrial level widescreen touch structure is rich in information, including setting temperature, sample temperature, oxygen flow, nitrogen flow, differential thermal signal, various switch states, etc.

2. USB communication interface, strong universality, reliable communication, support self-restoring connection function.

3. The furnace structure is compact, and the rate of rising and cooling is adjustable.

4. The installation process is improved, and the mechanical fixation method is adopted to completely avoid the contamination of the internal colloidal of the furnace to the differential heat signal.

5. The furnace is heated by heating wire, compact structure and small size.

6. The double temperature probe ensures the high repeatability of the sample temperature measurement, and adopts the special temperature control technology to control the temperature of the furnace wall to set the temperature of the sample.

7. The gas flow meter automatically switches between two channels of gas, with fast switching speed and short stable time.

8. Standard sample is provided for easy adjustment of temperature coefficient and enthalpy value coefficient.

9. Software support each resolution screen, automatically adjust the computer screen size curve display mode. Support laptop, desktop; Support Win2000, XP, VISTA, WIN7, WIN8, WIN10 and other operating systems.

10. Support user edit device operation mode according to actual needs to achieve full automation of measurement steps. The software provides dozens of instructions, and users can flexibly combine and save each instruction according to their own measurement steps. Complex operations are reduced to one-click operations.

3. Main Parameters:

- Temperature range: RT-500℃

- Temperature resolution:0.01℃

- Heating rate: 0.1~80℃/min

- Cooling rate: 0.1~30℃/min

- Calorimetric resolution: 100%. Under certain conditions, the two approximate thermal effects can be completely distinguished

- Constant temperature: RT-500℃

- Duration of constant temperature: The duration is recommended to be less than 24 hours.

- Temperature control mode: Heating, cooling, constant temperature, any combination of three modes cycle use, temperature uninterrupted

- DSC range: 0~±500mW

- DSC resolution: 0.01mW

- DSC sensitivity: 0.01mW

- Working power: AC 220V 50Hz 300W or other

- Atmosphere control gas: Two-channel gas control by automatic controlled (e.g. nitrogen and oxygen)

- Gas flow:0-200mL/min

- Gas pressure:0.2MPa

- Gas flow accuracy: 0.2mL/min

- Crucible: Aluminium crucible Φ6.6*3mm (Diameter * High)

- Calibration standard: with standard material (indium, tin, zinc), users can adjust the temperature coefficient and enthalpy value coefficient by themselves

- Data interface: Standard USB interface

- Display mode: 7-inch touch screen

- Output mode: computer and printer

- Fully closed support structure design, prevent items falling into the furnace body, pollution of the furnace body, reduce the maintenance rate

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China